JIAYAO CO.,LID

Product Description

Packaging Details: Telecom tower will be bundled by Galvanized strapping as per client's requirements.

Deliver:Shipped in 20 days after payment from Tianjin port

Tower members: One steel tower is separated into several bundles.

Bolts: Pacrum.lon bag or steel

We specialize in designing and manufacturing customized steel towers for telecom, monitoring, observation, and security applications. Below is the detailed product information:

| Design |

| 1. Design Code |

ANSI/TIA-222-G/H/F, EN 1991-1-4 & EN 1993-3-1 |

| Structure Steel |

| 2. Grade |

Mild Steel |

High Tensile Steel |

| |

GB/T 700:Q235B, Q235C,Q235D |

GB/T1591:Q345B, Q345C,Q3455D |

| |

ASTM A36 |

ASTM A572 Gr50 |

| |

EN10025: S235JR, S235J0,S235J2 |

EN10025: S355JR, S355J0,S355J2 |

| 3. Design Wind Speed |

Up to 250 km/h |

| 4. Allowable deflection |

0.5 ~1.0 degree @ operational speed |

| 5. Tension strength (Mpa) |

360~510 |

470~630 |

| 6. Yield strength (t≤16mm) (Mpa) |

235 |

355 |

| 7. Elongation (%) |

20 |

24 |

| 8. Impact strength KV (J) |

27(20°C)---Q235B(S235JR) |

27(20°C)---Q345B(S355JR) |

| |

27(0°C)---Q235C(S235J0) |

27(0°C)---Q345C(S355J0) |

| |

27(-20°C)---Q235D(S235J2) |

27(-20°C)---Q345D(S355J2) |

| Bolts & Nuts |

| 9. Grade |

Grade 4.8, 6.8, 8.8 |

| 10. Standards for mechanical properties |

| 10.1 Bolts |

ISO 898-1 |

| 10.2 Nuts |

ISO 898-2 |

| 10.3 Washers |

ISO 6507-1 |

| 11. Standards for Dimensions |

| 11.1 Bolts |

DIN7990, DIN931, DIN933 |

| 11.2 Nuts |

ISO4032, ISO4034 |

| 11.3 Washers |

DIN7989, DIN127B, ISO7091 |

| Welding |

| 12. Method |

CO2 Shielded Arc Welding & Submerged Arc Welding(SAW) |

| 13. Standard |

AWS D1.1 |

| Marking |

| 14. Method of marking of the members |

Hydraulic Press Stamping |

| Galvanizing |

| 15. Galvanization standard of steel sections |

ISO 1461 or ASTM A123 |

| 16. Galvanization standard of bolts and nuts |

ISO 1461 or ASTM A153 |

| Test |

| 17. Factory test |

Tensile test,Elements analysis, Sharpy test(impact test), Cold Bending,

Preece test,Hammer test

|

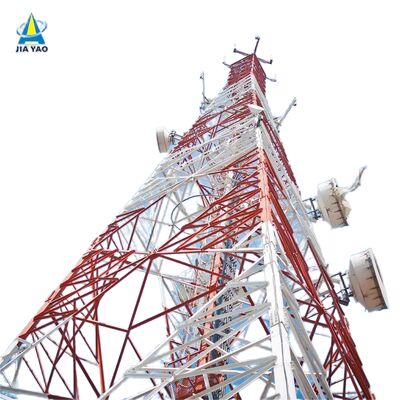

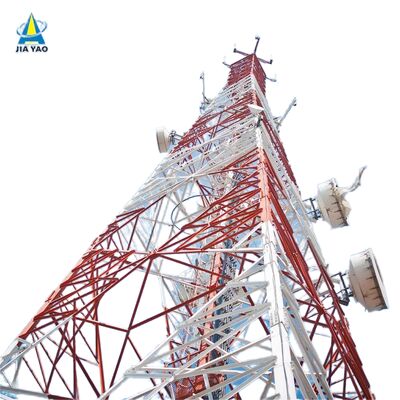

The lattice structure of a 4-legged angular steel tower is a crisscross, truss-like framework that connects the tower’s four vertical angle steel legs. Composed of interconnected steel members (typically angular steel or lattice bars), it forms a web-like pattern that distributes loads—including the tower’s own weight, equipment weight, wind, seismic forces, and ice loads—evenly across all four legs. This structure is integrated throughout the tower’s height, complementing the tower’s tapered design (wider at the base, narrower at the top) to enhance structural integrity and stability. The lattice configuration balances high strength with lightweight performance, minimizing material usage while maximizing load-bearing capacity and resistance to extreme environmental conditions. It also facilitates airflow, reducing wind resistance and further improving the tower’s overall stability.

Mounting a microwave (MW) dish on a 4-legged angular steel tower follows a systematic, safety-compliant process:

- Pre-installation Preparation: Verify the tower’s load-bearing capacity to ensure it can support the MW dish’s weight (including the dish, mounting bracket, and associated hardware). Check that the tower’s design complies with relevant standards (e.g., TIA/EIA-222-G/F) for equipment mounting.

- Bracket Installation: Attach dedicated antenna/microwave brackets (provided with the tower or custom-fabricated) to pre-designated mounting points on the tower’s body or equipment platform. These brackets are secured using high-strength bolts (complying with ISO 898 grade 6.8/8.8) to ensure a firm connection to the lattice structure or tower legs.

- Dish Lifting and Positioning: Use cranes or specialized lifting equipment to hoist the MW dish to the target height (typically on the upper sections of the tower or a dedicated equipment platform). Ensure the dish is aligned with the intended point-to-point communication path (adjust for azimuth and elevation as required).

- Securing the Dish: Fasten the MW dish to the pre-installed brackets using compatible hardware, tightening bolts to the specified torque with calibrated tools. Ensure the dish is level and stable, with no wobble or movement.

- Cable Routing and Integration: Route the dish’s signal cables through the tower’s integrated cable trays to protect them from environmental damage. Connect the cables to the appropriate equipment (e.g., transmitters/receivers) at the tower base or intermediate platform, ensuring proper insulation and waterproofing.

- Final Inspection: Conduct a visual check to confirm the dish is securely mounted, brackets are intact, and cables are properly organized. Test the dish’s signal transmission to verify alignment and functionality, adhering to safety protocols throughout the process.

The main structure of a 4-legged angular steel tower is a self-supporting framework designed for stability and load-bearing, consisting of three core components:

- Four Vertical Angle Steel Legs: The primary load-bearing elements, made of high-quality structural steel (e.g., Q235B, Q345B, Q420; compliant with ASTM A36/A572) and arranged in a square base configuration. These legs transfer the tower’s total weight (including equipment and environmental loads) to the foundation.

- Lattice Truss Connections: Crisscross steel members (angular steel or lattice bars) that link the four legs horizontally and diagonally. This truss system distributes loads evenly across the structure, enhances rigidity, and resists lateral forces (wind, seismic activity), forming the tower’s characteristic lattice pattern.

- Tapered Frame Design: The tower narrows gradually from the base to the top (wider at the bottom, narrower at the top), optimizing structural integrity by concentrating material where loads are heaviest (at the base) and reducing wind resistance at higher elevations.

Supplementary structural elements (e.g., equipment platforms, climbing ladders, and cable trays) are integrated into the main framework to support practical functionality, but the four vertical legs and lattice truss connections form the tower’s structural backbone.

A. Platform

- Purpose: Serves as an elevated, stable workspace for installing, maintaining, or inspecting equipment (e.g., MW dishes, 5G antennas, surveillance devices) and tower components. It also provides a safe resting point for workers during climbing.

- Design Features: Typically made of galvanized steel (complying with ASTM A123/ISO 1461 for corrosion resistance) and integrated into the tower’s lattice structure at specified heights. Platforms may include safety railings, non-slip surfaces, and access hatches to ensure worker safety. They are engineered to support the weight of workers, tools, and equipment, aligning with the tower’s overall load-bearing capacity.

- Customization: Can be added at multiple heights based on project needs (e.g., near antenna mounting points or mid-tower for maintenance).

B. Ladder

- Purpose: A dedicated safety access system that allows workers to climb the tower to reach platforms, equipment, or upper sections for installation, inspection, or repairs.

- Design Features: Constructed from galvanized steel for durability and corrosion resistance, with evenly spaced rungs (per industry safety standards) for comfortable climbing. Key safety features include handrails, fall-arrest systems (e.g., cable guides for harnesses), and sometimes cage enclosures to prevent falls. The ladder is attached vertically to the tower’s legs or lattice truss, ensuring a secure, stable path.

- Compliance: Designed in line with safety regulations and industry standards (e.g., TIA/EIA-222-G/F), prioritizing worker protection during vertical access.

Together, the platform and ladder enhance the tower’s usability by enabling safe, efficient access to high-altitude equipment and components, supporting ongoing operation and maintenance.

Galvanizing is a vital surface treatment for 4-legged angular steel lattice towers, providing long-term corrosion resistance to withstand harsh outdoor conditions and extend the tower’s service life beyond 20 years. Below is a simplified overview of its galvanizing testing:

1. Core Testing Objectives

- Ensure sufficient coating thickness for durable corrosion protection.

- Verify zinc coating uniformity and strong adhesion (prevent peeling/flaking).

- Check for no critical defects (e.g., bare steel, cracks, pits).

- Comply with international standards (ASTM A123, ISO 1461).

2. Key Testing Methods (Conducted post-factory and post-installation)

- Coating Thickness: Use magnetic thickness gauges (non-destructive) or micrometers (sample-only destructive); minimum 85–120 μm (thicker for harsh environments).

- Adhesion: Bend test (180°), hammer test, or knife cross-hatch test—no coating detachment allowed.

- Visual Inspection: Check for bare steel, cracks, uneven zinc buildup, or contamination; minor irregularities are acceptable if non-impacting.

- Corrosion Resistance: Salt spray test (ASTM B117/ISO 9227) for 100–500 hours (resist red rust); optional long-term field exposure.

- Optional Chemical Analysis: AAS/XRF to confirm ≥98% zinc purity and detect impurities.

3. Compliance Standards

Adhere to ASTM (A123, B117, A572), ISO (1461, 9227, 898), tower design codes (TIA/EIA-222-G/F), and local regulations.

4. Post-Installation Spot-Checks

- Re-measure thickness at critical joints.

- Inspect for damage (scratches, dents) and touch up with zinc-rich paint if needed.

- Verify coating integrity at bolt holes and high-wear areas.

This testing ensures the galvanized coating’s reliability, supporting the tower’s performance in infrastructure applications.

Packaging & Shipping

Certificates

Please Click Here For More Information!!!!!!

Customized product types & advantage

Self Supporting Tower

Self supporting tower usually is 3leg or 4leg tower, and its material is steel pipe or angle steel. As for the connection, tubular tower is connected by flange, and angle steel tower is connected by nuts and bolts.

Features:

1.Small coefficient of wind load, strong wind resistance.

2.Save land resource, convenient location.

Convenient transportation and installation.

Pipe Steel Tower

The tube tower refers to a self-supporting high-rise steel structure with a tower column made of steel pipes and a tower body section in a triangular shape. Its main characteristics are that the three tube tower column is made of steel pipes and the tower body section is in a triangular shape, which is a high-rise steel structure different from angle steel.

Monopole Tower

Monopole tower, is a commonly used type, with beautiful appearance, covering an small area of 9 to 18 square meter, cost - effective , and is adopted by majority of the construction. Tower body adopt more reasonable section, which is connected through high strength bolt or overlap(slip connection). It has the characteristics of easy installation and can adapt to a variety of complicated field site.

Guyed Tower

Guyed tower has a novel appearance,and its biggest characteristic is strengthened by using steel guy wire. Guyed tower is a common type of communication tower which is economical and practical. It is lighter and cheaper than the others. It is very suitable for the geographical wide areas.

Guard Tower

The watchtower is a multifunctional building mainly used for observing the surrounding environment and playing an important role in multiple fields. Its design emphasizes harmony and unity with the natural environment, and the architectural style is usually coordinated with the surrounding environment. Observation towers are usually composed of tower bodies, platforms, towers, and ladders, with compact and durable structures.

Camouflaged Tree Tower

Camouflaged Tree Tower is also a kind of cartificial trees of Bionic tree tower, on base like a real one, plus the meticulous design, when placed among the real trees in sightseeing area, park and square, it will be a part of the nature.

Features:

1. Exquisite structure and gorgeous appearance.

2. Strong structural stability and long working life.

3. Small area covering and great economic effect.

Our Services

JIAYAO CO., LTD. is a professional telecom tower manufacturer and approved by ISO9001. We are committed to providing customers with the most optimized solutions and the best communication tower. Many products have been exported to USA, Europe and other 55 different counties.

We specialize in designing and manufacturer of angle steel tower, tube steel tower, monopole tower, pine tree tower, guyed tower and guard tower. Our departments include design, R&D, inspection, laboratory, QC, galvanization and steel tower departments. Our raw materials come from famous steel mills in China: HBIS Group, Baowu Steel Group, Shougang Group.

If you need it, we will welcome you 24 hours a day!

يجب أن تكون رسالتك بين 20-3000 حرف!

من فضلك تفقد بريدك الالكتروني!

يجب أن تكون رسالتك بين 20-3000 حرف!

من فضلك تفقد بريدك الالكتروني!